tarp thickness guide

Understanding Tarp Thickness

Tarp thickness‚ crucial for durability‚ is measured in mils (1/1000th inch) or millimeters. Higher mil counts indicate thicker‚ stronger tarps better suited for heavy-duty applications. Understanding this is key to selecting the right tarp for your needs.

Measuring Tarp Thickness⁚ Mils vs. Millimeters

Tarp thickness is a critical factor determining its strength and suitability for various applications. Manufacturers often use different units to specify thickness‚ leading to some confusion. The most common units are mils and millimeters. A mil is one-thousandth of an inch (0.0254 mm)‚ a unit frequently used in the United States. Millimeters (mm)‚ on the other hand‚ are part of the metric system and represent one-thousandth of a meter. Therefore‚ a tarp listed as 10 mils thick is equivalent to approximately 0.254 mm. Understanding this conversion is essential when comparing tarps from different suppliers. Always check the unit of measurement to avoid misunderstandings and ensure you select a tarp with the appropriate thickness for your specific needs. Choosing the right thickness directly impacts the tarp’s durability and its ability to withstand various weather conditions and stresses.

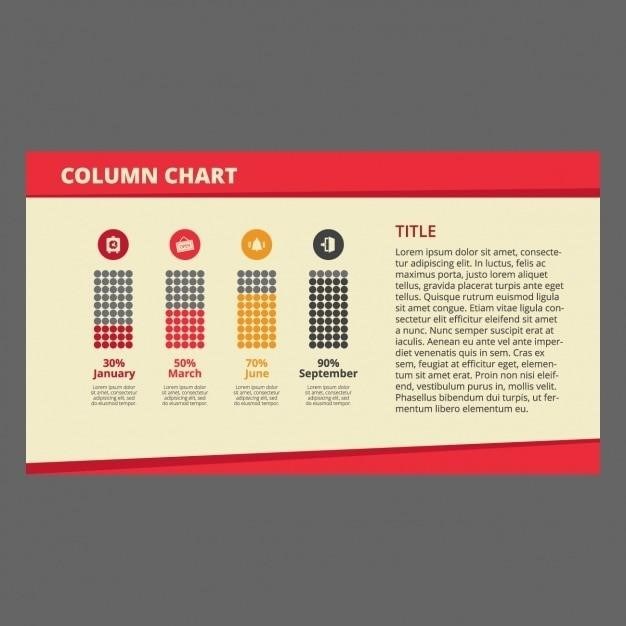

Tarp Thickness Chart⁚ Mil Counts and Their Applications

A tarp thickness chart helps visualize the relationship between mil count and tarp application. Lightweight tarps‚ typically ranging from 4 to 6 mils‚ are suitable for light-duty uses like covering small items or providing temporary shade. Medium-duty tarps (6-10 mils) offer increased durability‚ ideal for protecting equipment from moderate weather conditions or covering larger areas. Heavy-duty tarps (10-20 mils or more) provide superior protection against harsh weather and heavy use‚ making them suitable for construction sites‚ industrial applications‚ or protecting valuable equipment. The choice depends on the intended use and the level of protection needed. Thicker tarps‚ while more durable‚ are also heavier and less portable. Consider factors like weight‚ portability‚ and the severity of conditions when choosing the appropriate mil count for your specific application. Remember to always verify measurements and specifications with the manufacturer.

Factors Affecting Tarp Durability

Material density‚ weave count‚ and denier significantly influence a tarp’s tear resistance and overall lifespan‚ impacting its ability to withstand wear and tear.

Material Density⁚ The Key to Strength

While tarp thickness (measured in mils) offers a general indication of strength‚ material density is the true determinant of a tarp’s durability. Density refers to the amount of material packed into a given area‚ essentially how tightly the fibers are woven together. A denser tarp‚ even if it’s not the thickest‚ will generally be more resistant to tearing and punctures. Think of it like this⁚ two tarps might have the same thickness‚ but one is made of tightly woven‚ high-density material while the other is loosely woven with lower density. The denser tarp will be far stronger. This density is often not explicitly stated by manufacturers‚ making it harder to compare tarps directly based on this crucial factor. Therefore‚ consider reputation and reviews of the manufacturer when comparing materials of similar thickness. Paying attention to the weight per square yard can also be a useful indicator of density‚ although not a perfect measure. A heavier tarp per square yard generally means a higher density.

Weave Count and Denier⁚ Impact on Tear Resistance

Beyond material density‚ the weave count and denier significantly influence a tarp’s tear resistance. Weave count refers to the number of threads per inch in both the warp (lengthwise) and weft (widthwise) directions. A higher weave count generally translates to a tighter‚ more durable fabric‚ better able to withstand stress and resist tears. Denier‚ on the other hand‚ measures the thickness of individual fibers within the weave. A higher denier indicates thicker fibers‚ contributing to increased strength and tear resistance. Therefore‚ a tarp with a high weave count and high denier will typically be more resistant to tearing than one with lower values in either category. However‚ it’s crucial to remember that these factors interact with material density; a high weave count with low-density material may not offer the same level of protection as a lower weave count with high-density material. Always consider the interplay of these characteristics when evaluating a tarp’s strength and longevity.

Choosing the Right Tarp Thickness

Selecting the appropriate tarp thickness depends entirely on its intended use. Light-duty tasks need thinner tarps‚ while heavy-duty applications demand thicker‚ more durable ones.

Light-Duty Tarps⁚ Uses and Mil Range

Light-duty tarps‚ typically ranging from 4 to 6 mils in thickness‚ are best suited for applications requiring minimal protection from the elements. These thinner tarps are lightweight and easy to handle‚ making them ideal for various tasks such as covering small items‚ providing temporary shade‚ or protecting sensitive items from light rain or dust. Their lower weight allows for easier transportation and setup‚ making them a practical choice for camping‚ picnics‚ or other outdoor activities where portability is crucial. However‚ it’s important to note that their thinner construction means they offer less resistance to tears‚ punctures‚ or harsh weather conditions compared to heavier-duty options. Therefore‚ they are not recommended for applications involving heavy loads‚ prolonged exposure to extreme weather‚ or situations where significant protection from damage is required. Consider their limitations before using them for anything requiring substantial protection.

Heavy-Duty Tarps⁚ Applications and Mil Range

Heavy-duty tarps‚ boasting a thickness of 8 mils or more‚ offer superior protection against harsh weather conditions and potential damage. Their robust construction makes them ideal for demanding applications such as construction site coverage‚ protecting equipment from extreme weather‚ or creating secure enclosures. The increased thickness provides enhanced resistance to tears‚ punctures‚ and abrasion‚ ensuring the longevity of the tarp even under strenuous use. These durable tarps are frequently utilized in industrial settings‚ agriculture‚ and disaster relief efforts where reliability and resilience are paramount. While their thicker construction leads to increased weight‚ this is often outweighed by the superior protection and extended lifespan they provide‚ making them a cost-effective solution in the long run. Choosing a heavy-duty tarp is crucial for situations requiring substantial protection and long-term durability.

Tarp Material Considerations

Material choice significantly impacts tarp durability and performance. Poly‚ vinyl‚ canvas‚ and mesh tarps each offer unique properties‚ strengths‚ and limitations affecting suitability for specific applications.

Poly Tarps⁚ Properties and Limitations

Poly tarps‚ constructed from polyethylene‚ offer a compelling blend of lightweight portability and surprising durability. Their inherent water resistance makes them suitable for various applications‚ from shielding outdoor equipment to providing temporary shelter. Many are treated with UV inhibitors‚ extending their lifespan against sun damage. However‚ poly tarps exhibit temperature sensitivity; they can become brittle in freezing conditions and soften under intense heat. Their susceptibility to tearing and punctures necessitates careful handling‚ especially in environments with sharp objects or abrasive surfaces. While generally affordable‚ their longevity may be less than heavier-duty materials like vinyl‚ making them a cost-effective choice for shorter-term needs or light-duty applications where durability isn’t paramount. The inherent flexibility of poly tarps allows for easy shaping and adaptability to various surfaces‚ a significant advantage for many users. Ultimately‚ their suitability hinges on a careful consideration of the intended use and the environmental conditions they will face.

Vinyl Tarps⁚ Advantages and Disadvantages

Vinyl tarps stand out for their exceptional durability and robust construction‚ making them ideal for heavy-duty applications demanding superior protection. Their complete waterproofness provides reliable shielding against moisture‚ a crucial feature in demanding environments. Resistance to UV degradation and abrasion ensures longevity‚ even under harsh conditions. Many are treated with flame retardants‚ adding a layer of safety. However‚ this resilience comes at a cost; vinyl tarps are significantly heavier than their poly counterparts‚ impacting handling and transportation. Their price point reflects their superior quality and features‚ making them a more expensive option. While offering excellent chemical resistance‚ specific chemicals may still cause degradation. The lack of breathability can lead to condensation buildup‚ potentially damaging covered items. Ultimately‚ vinyl tarps represent a premium choice for applications requiring maximum protection and longevity‚ but their weight and cost should be carefully weighed against the specific needs of the project.

Additional Tarp Features

Beyond thickness‚ grommet spacing‚ reinforcement‚ rope hems‚ and corner construction significantly impact a tarp’s overall strength and securement capabilities. Consider these factors for optimal performance.

Grommet Spacing and Reinforcement

Grommets‚ metal eyelets used for securing tarps‚ are a critical feature affecting a tarp’s usability and longevity. Proper grommet spacing is essential for even tension and secure attachment. A typical spacing of 12-24 inches along the hem allows for effective tying down‚ preventing the tarp from sagging or tearing under stress. The material of the grommets themselves is also crucial; rust-resistant options like brass or galvanized steel are preferred for outdoor use‚ ensuring durability against harsh weather conditions and preventing corrosion. Reinforcement around the grommets further enhances the tarp’s strength‚ preventing tearing at these stress points. This reinforcement‚ often achieved through extra layers of material or stitching‚ significantly increases the tarp’s overall resilience and lifespan‚ especially important in heavy-duty applications where the tarp might experience considerable strain.

Rope Hem and Corner Construction

The rope hem and corner construction significantly impact a tarp’s durability and overall performance. A reinforced rope hem‚ running along all four edges‚ provides added strength and protection against tearing‚ especially in high-wind conditions. The thickness and material of the rope itself contribute to the hem’s strength; thicker ropes offer superior durability and resistance to abrasion. Corner construction is equally vital; double or triple-stitched corners with reinforced material significantly improve the tarp’s ability to withstand stress at these high-wear points. These reinforced corners prevent tearing and ensure the tarp remains secure even under significant strain. The quality of the stitching itself also matters; strong‚ even stitching is crucial for preventing unraveling and maintaining the structural integrity of the tarp’s corners and edges. Investing in a tarp with robust rope hems and reinforced corners ensures a longer-lasting and more reliable product capable of withstanding demanding conditions.